Piab has launched its new piGRIP FLC interface that expands the usability of all existing Piab suction cups. “Regardless of application, this product helps handling height differences and off-angle-picking in a simplified yet sophisticated waym,” said Lennart Ryberg, Product Manager of Piab Vacuum Automation Division. FLC stands for ‘Flexible Level Compensator’ and is designed to […]

Festo introduces a robust suite of pneumatic safety solutions

Festo introduces an innovative suite of safety products, including its new CIP safety module, that ensures the safe operation of pneumatic systems and lowers the risk of injury and system and product damage. Festo pneumatic safety solutions are compatible with the top industrial Ethernet protocols – EtherNET/IP, PROFITNET, and EtherCAT – which gives them near […]

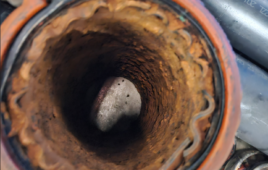

Compressed air fail: Pipe contamination

The typical piping installed in industrial plants and shops is made of steel, and as a result may be subject to rusting and contamination. Fig. 1 and 2 show what was found at a heavy industrial plant with the air compressors taking in polluted air. Rusting and contamination in compressed air system piping can lead […]

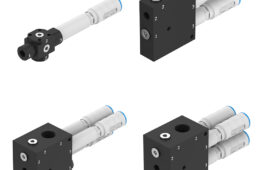

OVPN multistage pneumatic vacuum generator for porous materials

Festo has expanded its vacuum generation solutions to include for the first time a multistage generator and a multistage cartridge. These new vacuum components offer exceptional performance on porous materials, such as paper and corrugated board. The OVPN multistage vacuum generator and the OASP vacuum generator cartridge are ideal for such applications as overhead palletizing, […]

Norwegian fisheries rely on liquid ring vacuum pumps for packaging

Norway has a long tradition of catching and processing fish. The country ranks second in the world for exports behind China. To ensure the high quality of their freshly caught products, Norwegians pay particular attention to an unbroken cold chain. One company that contributes to a high level of food safety is Atlantic Styro. Based […]

Festo’s new VTUX valve terminal boasts modular design for flexible use

Festo introduced the new VTUX flagship valve terminal, which can serve as I/O, remote I/O, and decentralized I/O. These compact and rugged IP65/67-rated terminals can be located anywhere on a machine that boosts operational performance and original equipment manufacturer (OEM) installation productivity. VTUX modularity results in less inventory and lower overhead costs. VTUX is both […]

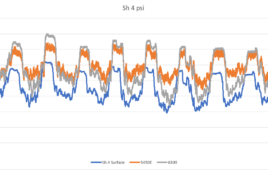

Compressed air fail: Pressure increase

Normally when measuring the pressure gradient of a compressed air system in an industrial site, the pressure at the compressor discharge is the highest of all locations. Once the compressed air travels through piping, filters, air dryers, and other components — each causing restriction to flow — the pressure at the far end of the […]

Improving packaging applications with pneumatic control

Increase efficiency and effectiveness by choosing the right pneumatic control or regulation product for accurate, repeatable results. By Mindy Schoeff, Marketing Communications Manager, Proportion-Air Facilities that manufacture packaging products, or those that do the actual packaging, are no strangers to pneumatic control. Whether pressing a product, filling it, conveying or moving materials, testing or sealing, […]

Pack Expo Chicago is ready for record numbers

The world’s largest packaging and processing show returns to Chicago’s McCormick Place November 3-6. Pack Expo International, scheduled for Nov. 3–6 at McCormick Place in Chicago, is set to be the largest packaging and processing show worldwide for 2024. According to PMMI, The Association for Packaging and Processing Technologies, the industry’s growth underscores the need […]

ELGi introduces next-generation, highly efficient EG series air compressors

ELGi North America has upgraded its EG series portfolio with the introduction of the EG Super Premium (EG SP) 90-110 range of oil-lubricated screw air compressors and the EG PM 11-45kW Permanent Magnet Synchronous Motor (PMSM) compressor. Engineered to meet the evolving demands of industries worldwide, the new units maximize energy savings and reduce environmental […]

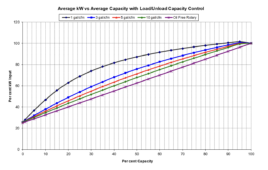

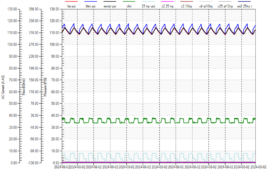

Compressed air fail: Load/unload

In this blog post, we will discuss the third of five industrial compressor capacity control modes. A moderately efficient method of controlling a compressor at part load uses load/unload mode with adequately sized storage receiver capacity. With this mode, a pressure switch, or electronic control, is used to provide load and unload signals to the […]

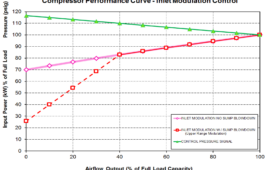

Compressed air fail: Modulating mode

In this blog post, we will discuss the second of five industrial compressor capacity control modes. The least efficient method of controlling a compressor at part load is using modulating mode by way of pneumatically controlled inlet valve control. With this mode, a pneumatic system detects the compressor discharge pressure and compares it to a […]

Compressed air fail: Start/stop mode

In this blog post, we will discuss the first of five industrial compressor capacity control modes. The simplest method of controlling a compressor is Start/Stop mode using pressure switch control. This control simply turns on the compressor to run at full load when the pressure hits a lower pressure level — and turns off the […]

Compressed air fail: Variable displacement

There are five different capacity control modes available for use with North American-built large industrial air compressors. It pays to know how each mode works, especially if you operate or service air compressors or happen to have your compressors operating in one of the least efficient modes. The accompanying photograph shows just one design that […]

Optimize air-operated double diaphragm pump with control unit

Ensuring that air-operated double diaphragm pumps run consistently and optimally through long cycles is easy with Proportion-Air’s new Pump Controller. Many AODD pumps operate with just a ball valve and shop air. This can lead to inaccurate, inconsistent material flow. The Pump Controller is a turnkey system that eliminates these issues. Run-dry situations can be […]

Compressed air fail: Air-oil separator failure

A compressed air auditor regularly flow-tested the compressors under his study. This generally would be done if the air compressor was drawing low amps — a telltale sign that the unit is producing low flow output — or if the compressor has excessive hours. Often times, internal wear due to age will reduce output […]

Clippard launches EHS high-pressure electronic valves

The EHS series of high-pressure electronic valves from Clippard is precision-engineered to deliver robust performance in higher pressure (up to 1,000 psig) applications, prioritizing both safe functionality and the reduction of potential leak points. Building upon the foundation set by the ES series, the EHS incorporates key features such as substantial cross sectional O-rings, proven […]

Why use point-of-use dryers with compressed air systems?

It is common to see the air in a complete plant dried by a desiccant dryer only to service one small end-use that is subject to freezing temperatures. The purge from a large desiccant dryer is much more costly than that of a small point-of-use dryer, which can be placed on the outdoor feed. The […]

New Proportion-Air Supply benchtop testing device saves time

Proportion-Air is expanding its proportional electro-pneumatic pressure and flow control into the testing equipment field with its newest product, the Proportion-Air Supply. This benchtop unit for lab or manufacturing use is designed to regulate compressed air and other gases within prescribed pressure and flow limits for easy use. Suitable for developing, testing, and diagnosing pneumatic […]

Which pneumatic technology is best for linear motion applications?

In linear motion applications, pneumatics, servo pneumatics, and controlled pneumatics each deliver unique motion and force capabilities. Contributed by By Frank Langro, Director of Product Market Management, Pneumatic Automation, Festo Pneumatic linear actuators are fundamental for automation because of their low cost, ease of installation and operation, high yet compliant force, speed, compactness, safety in hazardous areas, […]

Compressed air fail: No log

A compressed air auditor was excited to see logbooks for each of the compressors at a large mineral processing facility. Each book was protected from the environment by a really nice orange plastic case. The auditor was interested to see the compressor history and opened the book, only to discover it was blank — no […]

Compressed air fail: Clutch play

A compressed air auditor recently performed an energy audit at a mineral processing facility. Plant personnel were constantly complaining about production outages due to low pressure. The problem was that when the pressure dips down below 80 psi, the drive clutches on the large ball mills — that grind the processed down minerals to powder […]

Compressed air fail: Condensate disposal

A compressed air auditor found, during a site visit to a mine, that compressed air condensate was left to drain from stopcock at the bottom of piping low spots. The oily condensate pooled on the ground, creating a slippery mess that polluted the environment and caused a safety hazard. This mine had no air dryers […]

Compressed air fail: The bag method

Did you know that garbage bags have a use in the compressed air industry? The use of garbage bags to determine compressed air leakage, is described in the U.S. Department of Energy’s (USDOE) MEASUR tool and is a straightforward and cost-effective method for roughly estimating air leaks in a compressed air system. This technique is […]

New pneumatic robotic tool changers from SMW Autoblok

SMW Autoblok just launched a new line of quick-change, pneumatic robotic tool changers that can be combined with various pneumatic grippers and C40 inductive couplers for contactless, wear-free energy and signal transmission. With these new products, grippers, tools, and other end effectors can be changed quickly to increase cycle time and productivity and are effectively […]